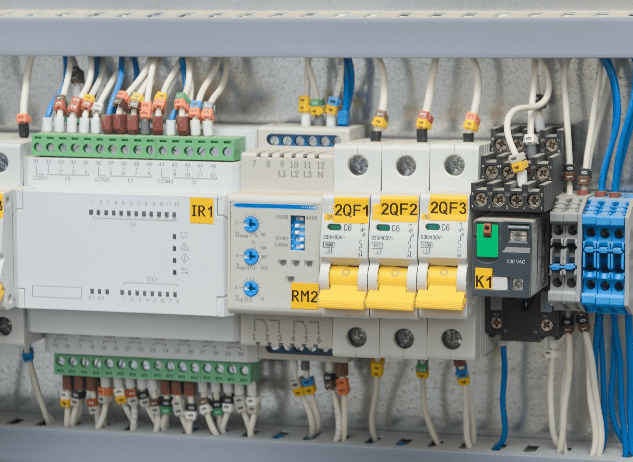

Programmable Logic Controller

What are PLCs?

PLCs are used to automate various industrial processes such as assembly lines, processing plants, or wastewater treatment plants. The programmable logic controller receives information from connected input devices and sensors, processes the data, and triggers required outputs as per its pre-programmed parameters.

We ensure that all our PLCs are programmed to function at optimal capacity within a rough industrial environment, thus minimising the risk of breakdown. We work closely with customers to ensure their PLC is programmed according to the operational requirement of the process.

PLC Application

PLCs will continue to grow in prominence due to the rapid advancement in automation technology. Programmable logic controllers are an essential component of any system that involves some degree of modern machine automation.

PLCs perform a wide variety of functions including:

-

Conveyor belt systems

-

Packing and labelling systems

-

Automatic liquid filling systems

-

Complex data recording

-

Manufacturing and/or mixing quantities of materials

-

Automatic drainage water pump monitoring and controlling

-

Time and count-based control systems

-

Temperature and humidity controller

-

Fault detection and protection of machinery

-

Energy management systems

Our PLC Process

Based on its inputs and outputs, a PLC can easily monitor and record runtime data which makes it very adaptable to most applications.

Some of our process involves:

- Understanding the safety requirements of the machine or process

- Specifying required Inputs / Outputs

- Reviewing the sequence of operation

- Industrial network requirements

- PLC code configuration and software development

- Offline and online program testing