Machine Vision Systems

What are Machine Vision Systems?

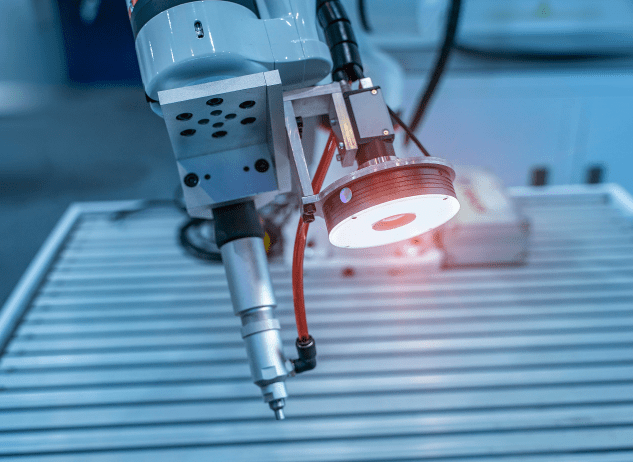

Vision technologies have become an integral component of quality control manufacturing, as methods used to provide image-based automatic inspection and analysis for such applications as automatic inspection, motion control and robot guidance.

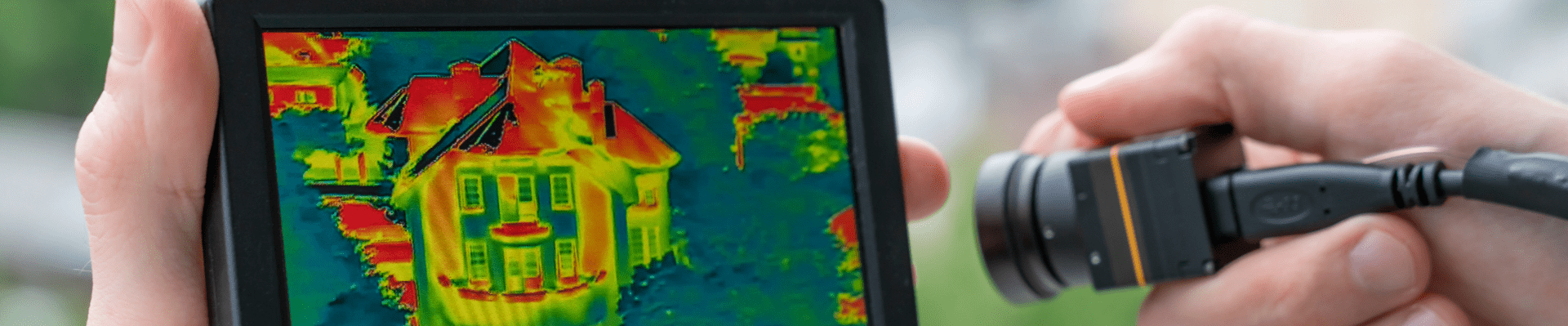

Machine vision uses a camera and a computer to perform a specific task.

More specifically, these systems use a camera to obtain the necessary part images, and then use a computer to analyse the images and respond accordingly to data – often inspecting the part with a pass/fail outcome.

Benefits of Vision System Integration

What are the operational benefits of integrated vision systems?

For businesses looking to scale their operations through automation, there are many benefits to integrating machine vision, including:

-

Higher productivity and output

-

Lower costs – Less downtime and waste

-

Improved product quality

-

High-frequency inspections

-

More stringent compliance with industry regulations

-

Increased safety – machine vision solutions contribute to a positive, safe working environment

-

Improvements to sustainable working practices

-

Increased innovation – Releasing staff from manual, repetitive tasks for higher-value work

Why Choose Shamrock for your Vision System Integration

At Shamrock, we specialise in the vision system integration of several important functions including; automated inspection, error-proofing, quality control, testing, guidance and robot control.

We design and implement leading-edge vision systems and machines that enable high-precision machine vision inspection, verification and analysis. We have extensive experience across a wide range of industries. Everything from pharmaceutical, to automotive, semiconductor, and food production and packaging.

Whatever you manufacture and whatever industry you specialise in, we have a solution to help bring your business to the next level through automation.